Category: Uncategorized

New Cuff Clip Multi Handcuff Holder

Handcuff Warehouse is reintroducing the multiple handcuff holder. The Cuff Clip can be used to secure up to 13 pairs of handcuffs to your duty belt. The Cuff Clip is designed to fit onto a 2.25 inch duty belt and is constructed of nickel plated carbon steel. Nickel plating provides a nice finish as well as corrosion resistance for years of duty use.

Correctional officers have been asking for these to be made again and we answered the call.

4 Things You Need To Know Before Using Handcuffs

Guest post by Ralph Goodman

The modern advancements in handcuff technology can make the use of restraints seem deceptively straightforward. For the most part, these devices are rather intuitive, but there are still things about handcuffs that everyone should know before using them. You want to know a bit about the device so that you can understand how to use it most effectively. This information is only intended for lawful restraint and should also not be used to avoid law enforcement custody. With that being said, let’s talk about the things you need to know before using handcuffs.

- How the Locking Mechanism Works

Knowing how the locking mechanism on your handcuffs work is going to allow you to get the most out of the restraints. Say for example you have double locking handcuffs. Failure to engage both locking systems means you are not applying the maximum amount of security. But not all double locking mechanisms are the same. You might need a key to depress a push pin double lock or use just have to use your thumb to activate the double locking feature. It is of the utmost importance that you know the full extent of the security you can get out of a pair of handcuffs and how to use it.

More than how to lock your handcuffs most effectively, you should also know how the cuffs are locking. Throughout the history of handcuffs, these devices have gone through many iterations. However handcuffs have not changed that much in recent decades, and the most likely type of handcuffs that you will encounter will use a ratcheting system that allows the cuffs to tighten and not to loosen. It is only when the proper key is inserted that the locking pawl on the ratcheting mechanism can be separated from the teeth of the cuffs. With this separation, the teeth no longer catch on the pawl and the cuffs can slide freely open.

- The Vulnerabilities of Your Restraints

Once you know how the locking mechanism for your particular set of handcuffs works, you can better understand their vulnerabilities. In the case of handcuffs that use a ratchet and tighten method of securing, it will be possible for restrained individuals to shim the lock. This method of escape relies on using a small feeler gauge that is inserted between the teeth of the cuff and locking pawl. This creates a boundary similar to the gap that is caused by inserting the proper key.

In understanding your locking mechanism, you have likely discovered that standard handcuff keys do not commonly have unique key profiles. This means that handcuff keys are not hard to come by. And even if the key is not widely available, any lock can be picked. But if none of this is a concern based on the type of individual in custody, a thorough search process, etc., there are still ways that certain restraints can be snapped or leveraged into breaking. Be sure you know the most likely way people will attempt to escape your handcuffs.

- How To Observe The Detainee

The vulnerabilities of your particular restraints will give you insight into how it may be necessary to watch the person under your charge. With restraints that use plastic cables, such as zip tie material, it is important that you do not allow the restrained individual to lift their arms over their head. This is a commonly used method for snapping these restraints. If they begin trying to tighten the restraints this can cause a few issues, but it is often done to prep the restraints for an attempt at snapping.

For more substantial metal handcuffs, be aware that the person being restrained might attempt to leverage the chain connecting the cuffs (if this is the type of connection being used) to snap the chain. Be vigilant for fidgeting shoulders and the sound of metal on metal. Unless the person under your surveillance is extremely proficient with escape, you do not have to be overly concerned with shimming, picking, or the use of concealed handcuff keys. These are more advanced methods, and without the proper tools/materials, they are not likely to even be attempted. Just to be safe, if the person’s hands are behind their back, keep an eye on their wrists.

- The Dangers of Improper Use

After you are getting the most out of your restraints, knowing the most likely ways someone is likely to try to exploit their handcuffs, and keeping an eye on them to make sure no attempt they make is successful, it is important to make sure you have done everything properly. Issues such as handcuff neuropathy (wrist compression that damages nerves) have largely been curbed due to advancements in handcuff technology, but this type of thing can happen if the cuffs are too tight, or there is no handcuff wrist protection.

Once someone is under your charge, it is important that they are not injured by their restraints. Having the handcuffs too tight is the most likely way to do harm. If restraints must be kept tight, be sure that this is not done for an extended period of time, but always avoid any unnecessary tightness. Restraints can also tighten due to the movement of the person wearing them. Periodically check that the individual is not harming themselves by improperly using the handcuffs.

Conclusion

Knowing about your handcuffs’ locking mechanism(s) will also give you insight into how they might be exploited. If you know how the restraints are vulnerable, you can take steps to prevent this through observation of the detainee. From there, it is just a matter of making sure you do not make a mistake and do harm with your handcuffs. These mistakes largely center around the tightness of the handcuffs around a person’s wrist, which the person wearing them may exacerbate. Use this information lawfully to ensure the safety of yourself and your detainee.

Yuil Handcuffs From South Korea

Exciting things are happening at the Handcuff Warehouse this week. We just received a shipment of Yuil handcuffs from South Korea. After a period of unavailability from us we are glad to now have the full line of Yuil back in stock.

Yuil M05 thumbcuffs are a favorite among collectors. These feature two keyholes and two double lock slots, one for each cuff so they operate individually. The special thumbcuff key makes these extra secure as it is unique to this product.

Another spotlight in the Yuil product line are the aluminum handcuffs. There are now quite a few Aluminum handcuffs on the market, but the special key Yuil uses makes these more secure than your standard US made aluminum cuff. The only drawback being the unique keys, you do not want to attempt to open these with a standard key as it will ruin the cuffs.

Thats’s not all though. Head over to our website and check out all 15 models of Yuil handcuffs that are back in stock!

Handcuff Talk

“Modern” Handcuffs: Some things never change

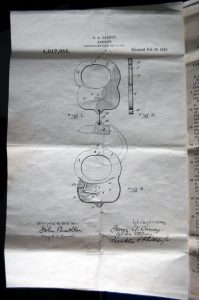

Like it or not handcuffs play an important role in modern society. There aren’t many, if any products that were designed in the early 1900’s that are still being used today in almost identical form to the original. The modern handcuff design was patented in 1912.

These handcuffs featured a swinging arm that can rotate all the way around a pivot and through the double strand that makes up the body of the handcuffs. This feature along with a cleverly designed simple locking mechanism made restraining criminals much safer for officers than rugged Darby style handcuffs.

The keys those handcuffs used are strikingly similar to that of a modern handcuff key. Early Peerless handcuff keys were not hollow like their modern day counterparts. They instead featured a “post” at the end of the bit that would fit into a small hole on the opposite side of the handcuffs keyway. These early swing through handcuffs were manufactured and most widely used for the next 20 years.

In 1932 the Peerless Handcuff Company released the next version of their already popular design. These handcuffs were more streamlined than the originals, and they also featured what we know as a universal handcuff key. 85 years later these keys would still open a pair of handcuffs coming straight off the assembly line. Although virtually all the handcuffs used by a street officer use the same key, these restraints are still extremely secure. Due to the positioning of the keyhole and modern handcuffing techniques it is extremely difficult to escape a pair of handcuffs, even if the criminal has access to a key.

A standard pair of modern handcuffs is constructed of nickel plated carbon steel. Nickel plating helps protect the raw steel from water and oxygen, preventing rust from forming. There are now many different finishes manufacturers employ to protect the metal handcuffs are constructed of. Smith & Wesson has a popular finish they call Melonite. Melonite is a process that turns metals black, and also creates a barrier that goes deeper into the metal to prevent oxidation. Another similar method used by Smith & Wesson, Peerless and other manufacturers is Bluing.

More recently manufacturers started color coating their handcuffs. Smith & Wesson made some for a few years with a Weathershield coating, a very durable paint that they also use in gun manufacturing. Peerless employs an electrolytic polyurethane process to color plate their restraints. CTS powder coats their handcuffs. ASP uses colored polymer over molds on their colored handcuffs.

HANDCUFF WAREHOUSE ACQUIRES KeyCuff

Handcuff Warehouse is proud to announce another acquisition. This month we acquired the company KeyCuff. KeyCuff manufactures reusable nylon restraints. To learn more about KeyCuff please visit our newly launched KeyCuff website. http://keycuff.com/

Handcuff Warehouse Acquires Tuff-Tie

This week we finished finalizing our acquisition of Tuff-Tie Inc. We have began manufacturing their products in Norfolk, VA and will be releasing a new cutter in the weeks to come. We are very excited to be expanding our manufacturing capabilities and are committed to serving current and future Tuff-Tie customers.

Tuff-Ties are nylon braided disposable restraints. They are not nearly as bulky as traditional disposable restraints and up to 10 can be carried comfortably in a standard pant pocket. Compact, yet strong. Tuff -Ties have a breaking point at over 500lbs.

We will be manufacturing hand & foot restraints as well as the transport hobble. We have a newly designed cutter that is also made in the USA that will be released soon.

Double Locking Handcuffs

All the handcuffs we sell at the Handcuff Warehouse have double locks. Across the various manufacturers we deal with there are 3 types of double locks: Slot Lock, Push Pin and Lever Lock. When a set of handcuffs is double locked, they cannot be tightened without disengaging the double lock with a handcuff key.

Slot Lock:

Most Smith & Wesson and all ASP handcuffs feature the slot lock double locking system. For both brands there is a double lock slot on both sides of the cheek plate. To double lock Smith & Wesson slot lock handcuffs insert the double lock pin on your handcuff key into the top of the slot, and pull down towards the keyhole until you feel or hear it click.

To double lock ASP handcuffs insert the pin on your handcuff key into the slot and pull away from the keyhole. You can also double lock ASP handcuffs by inserting the handcuff key into the keyhole and turning they key clockwise.

Push Pin Double Lock:

Push pin double locks are very popular. Advocates of the push pin system say the push pin is easier to use than the slot lock, especially in low light situations. All Peerless, Hiatt, Chicago and CTS handcuffs feature push pin double locks. The push pin on all the different brands of handcuffs is in the same place, the outer top edge of the cuffs right under the double strand. To engage the double lock simply push the double lock pin on your handcuff key into the double lock hole until you hear or feel a click.

Lever Locks:

Smith & Wesson’s M&P lever lock handcuffs are still relatively new to the market having just come out a few years ago. The only US made handcuff with a finger activated double lock. The double lock levers on these handcuffs are located in the same place as the push pin on other cuffs, only you do not need a key to activate the lock. Simply use your finger to pull the lever up and away from the keyhole until you hear or feel the click of the lock activating.

Handcuff Finishes

Handcuff Finishes

Nickel: Nickel plating is the most popular handcuff finish. Our two best sellers, the Smith & Wesson Model 100 and the Peerless Model 700 both are nickel plated handcuffs. Smith & Wesson does a satin nickel finish on their handcuffs giving them a rougher appearance that is less reflective, and easier to grip. Peerless’ nickel finish is much more shiny and smooth. CTS, Hiatt, ASP and Chicago also nickel plate a majority of their restraints.

Blued: Bluing (black oxide), not the actual color blue, but the same process used to protect firearms and make them black. Blued handcuffs are very popular. Bluing is used to add mild corrosion resistance to handcuffs. Black oxide finishes require regular lubrication to remain rust-free. Smith & Wesson, Peerless and Hiatt all have blued (black) handcuffs in their lineups.

Melonite: Melonite is trademarked salt bath nitriding process used to blacken handcuffs and increase surface hardness. S&W uses the same process on their guns. Glock uses a very similar process called Tenifer They have two models of Melonite handcuffs: their standard model 100 in a Melonite finish and their M&P Melonite handcuff with finger activated double locks.

Stainless: There aren’t many stainless steel handcuffs on the market today. Stainless steel is used in a variety of applications because it is extremely resistant to rust.

Colored Handcuffs

Color Plated: Peerless Handcuffs are available in 5 different colors. The color coating is applied using a process called Electrolytic Polyurethane Plating (EPP). EEP fully coats restraints inside and out without interfering with the lock mechanism and jaw swing through.

Powder Coated: CTS (formerly Hiatt-Thompson) colored handcuffs are powder coated. As part of their process, the end of the swinging arms of CTS handcuffs is not fully coated.

Weathershield: Smith & Wesson calls their colored handcuffs Weathershield handcuffs. Smith & Wesson coats the whole handcuff except the chain and swinging arm in a durable colored finish.